Fermentation juice separator

The effective solution for the discharge and separation of digestate/silage and surface water.

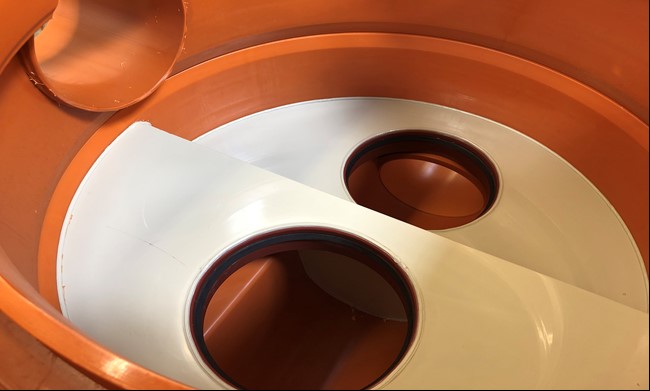

Fermentation juice/silage are separated from the surface water by a two-chamber system with a separating bottom over two levels. The simple plug-in technology and the polypropylene (PP) material are outstanding features for use in mobile silo systems. Only these components can be safely welded with the IP-plus welding system. We guarantee this!

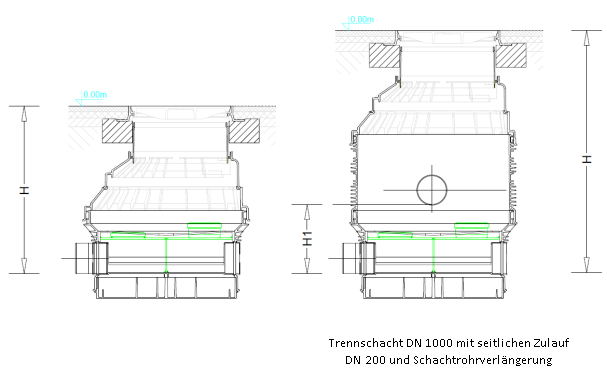

Appropriate DN 400 riser pipes can be used to extend the manhole. If side inlets are required, they can be obtained from our company.

The covers are installed by means of in-situ concrete frames. The special SABUG swelling seal ensures a permanently tight connection between the plastic manhole pipe and the concrete frame. All SABUG manhole systems are designed for traffic loads up to SLW 60 (10 tons wheel load).

Before delivery, each manhole body is subjected to a leak test. The leak test in accordance with DIN EN 1610 is carried out on the components intended for storage and discharges in order to prove sufficient strength and leak tightness (see drawing).

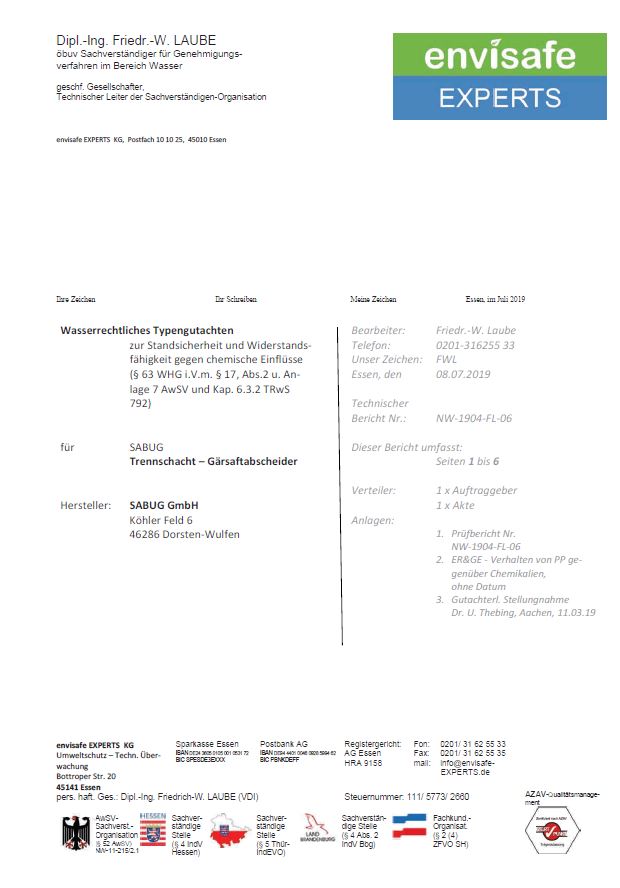

Our products comply with the requirements of the new worksheet DWA-A 792 on the technical rule for water-polluting substances “JGS plants” TRwS 792 in the DWA rules and regulations. TRwS 792 represents the basis for planning and construction of future storage facilities.

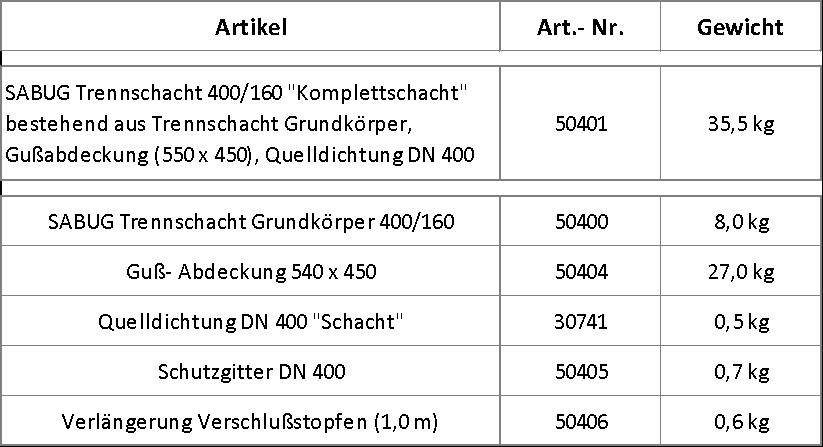

New! Separation chamber DN 400/160 now available complete with matching cast cover D 400. (Separation chamber bottoms are of course still available individually).

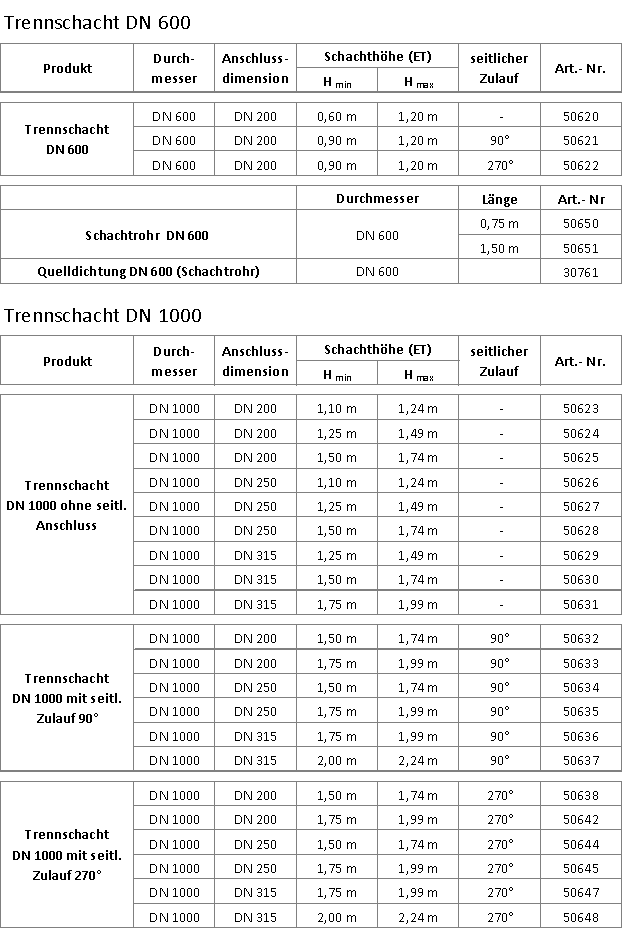

Separation manhole DN 600 and DN 1000

Quality Assurance Separation Shafts:

SABUG separating chambers DN 315 to DN 1000 have a water-legislative type certificate for separating chambers DN 315 to DN 1000 as proof of suitability for use in accordance with TRwS 792 and in the sense of § 63 WHG in conjunction with § 17 AwSV.

All DN 400 separation chambers are given a serial number during production. This means that the manufacturing processes can also be traced at a later date.

Furthermore, they are subjected to a leak test according to DIN EN 1610 during production. (0.5 bar, 15 min.) This ensures that both chambers are tightly welded to each other and to the ground. Each chamber then has a leak test certificate.

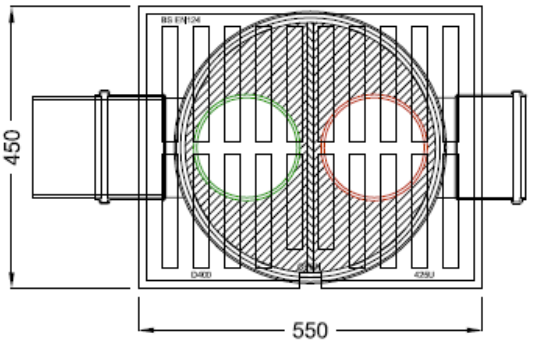

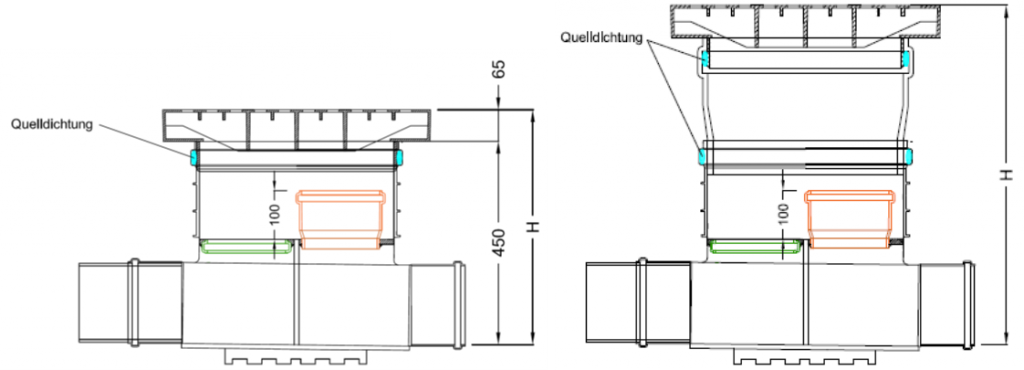

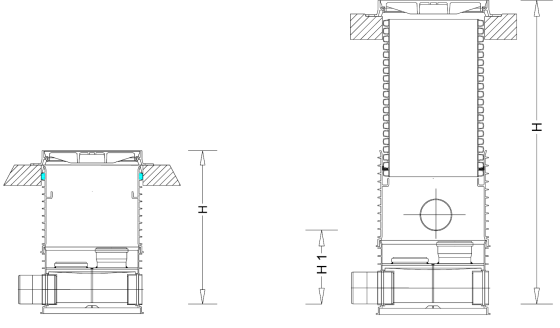

Drawings and examples of cover

Separating shaft DN 400

Separating shaft DN 600

Note: All dimensions given here are example dimensions. The dimensions may vary depending on the project!

Separating shaft DN 1000

Note: All dimensions given here are example dimensions. The dimensions may vary depending on the project!