Many containers must be monitored according to the technical rules for substances hazardous to water (TRwS) or due to other conditions! The monitoring must function reliably and automatically. SABUG offers the appropriate solutions for all these requirements. Complete solutions, matching the tank system with the required probes, professional probe mounts, cabling (also according to WHG) as well as the control cabinet technology can be realized with this system.

Many containers must be monitored according to the technical rules for substances hazardous to water (TRwS) or due to other conditions! The monitoring must function reliably and automatically. SABUG offers the appropriate solutions for all these requirements. Complete solutions, matching the tank system with the required probes, professional probe mounts, cabling (also according to WHG) as well as the control cabinet technology can be realized with this system.

When designing the monitoring unit, customer requirements are taken into account to the same extent as the legal requirements. Corresponding warning devices such as a horn or rotating beacon are also components of the sensory equipment. Of course, all components of the monitoring system comply with the requirements of the Water Resources Act (WHG) if required and have the approvals for WHG and ATEX. The entire sensor system is pre-assembled in the factory and delivered to the construction site as a “plug and play” version. Only the cables have to be laid and connected to the control cabinet according to the connection diagram.

Sensors and monitoring technology

- Leakage monitoring

- Level indicator (continuous)

- Overfill protection

- Pump control

- Flow measurement

- Temperature detection

Leakage monitoring

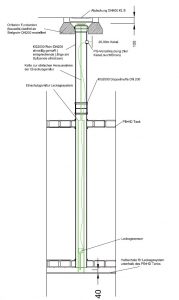

The Sabug container and tank systems basically have a double-walled structure. This allows the tank to be easily and reliably checked for leaks and also monitored online! Thanks to the special manufacturing method of the closure bottoms (dished bottoms), the container can be monitored in its entirety.

Monitoring takes place inside the hollow profile. Through appropriate connection channels, the entire tank is monitored with one probe. The sensor system is based on a conductive probe system that sounds an alarm as soon as a liquid enters the cavity profile.

It is irrelevant whether the liquid penetrates from the outside or from the inside.

This ensures 100% detection of leaks in all areas of the system.

Monitoring with over- or suppression is deliberately not used here, as ignitable mixtures could also accumulate in the interstices in the “tight” containers due to so-called “permeation”. Here, too, the sensors and probes are equipped with WHG or ATEX approval. Redundancy is of course possible at any time by using a second probe system.

Level and overfill protection

The level measurement is carried out by means of a radar probe system as standard. Ultrasonic probes and pressure cans have not proven themselves for use in underground containers, since fog formation or sediments hinder the measurement recording and provoke false alarms.

The overfill protection is preset by us to 95% alarm level at the factory, but can be reprogrammed on site if required. Continuous and discontinuous level measurement allows the filling quantity in the container to be shown on a display on the control cabinet.

Of course, all other sensors, such as flow meters or similar, can also be integrated into the tank technology. We will be happy to advise you and lay out the tanks individually for your needs.