JGS facilities house valuable feed or fertilizer, but at the same time they can pose an environmental hazard if not properly constructed or operated. When storing silage in a flat silo, the escaping fermentation juice is the reason for the special requirements placed on the structural system.

Defective JGS facilities, such as mobile silo facilities, repeatedly lead to contamination of the groundwater or the receiving waters, streams and rivers located in the neighborhood. Fermentation juice can reach pH values between 4 and 5 due to the acid formation during the fermentation process. The components used must therefore have an appropriate acid resistance. In addition, special attention must be paid to the tightness of the construction, as fermentation juice is classified as hazardous to water. According to the Water Resources Act (WHG) § 62, fermentation feed silos must be built and operated in such a way that the best possible protection of water bodies is achieved.

To protect the environment, the legislator has now reacted:

On 01.08.2018, the Federal Council put into force the new Ordinance on Installations for Handling Substances Hazardous to Water (AwSV), which will regulate the handling of substances hazardous to water in the future. In addition, the new TRwS 792 (Technical Rule for Substances Hazardous to Water) for JGS plants has been published. TRwS 792 harmonizes the 16 legal ordinances of the federal states (RVO) that regulate the handling of JGS systems and now combines them in one technical rule. In future, TRwS 792 will have the character of a “generally recognized rule of technology” and will be legally binding in accordance with the Water Resources Act (WHG). This means that this rule must be applied. This applies to fixed or stationary facilities for the storage and filling of liquid manure, slurry, silage leachate, fermentation residues and solid manure.

In accordance with this regulation, for example, all wastewater pipes that discharge substances hazardous to water must now be friction-locked, i.e. welded or bonded. Storage tanks must in many cases be double-walled and above 25 m³ volume must be equipped with leakage monitoring or overfill protection.

To meet the new requirements, SABUG has developed a complete system for the drainage of AwSV plants

With a comprehensive quality concept, all projects are accompanied in accordance with the regulations.

From planning and production to delivery of the required components.

All products are manufactured with the highest level of know-how.

The IP-plus welding system has general building authority approval from the German Institute for Building Technology (DIBt).

The project-specific tank and container systems are always delivered with a works certificate in accordance with DIN EN 10204, a static calculation and a factory leak test.

Examples of execution

There is a wide range of designs and variants for the drainage of silage systems. All solutions have specific advantages and disadvantages.

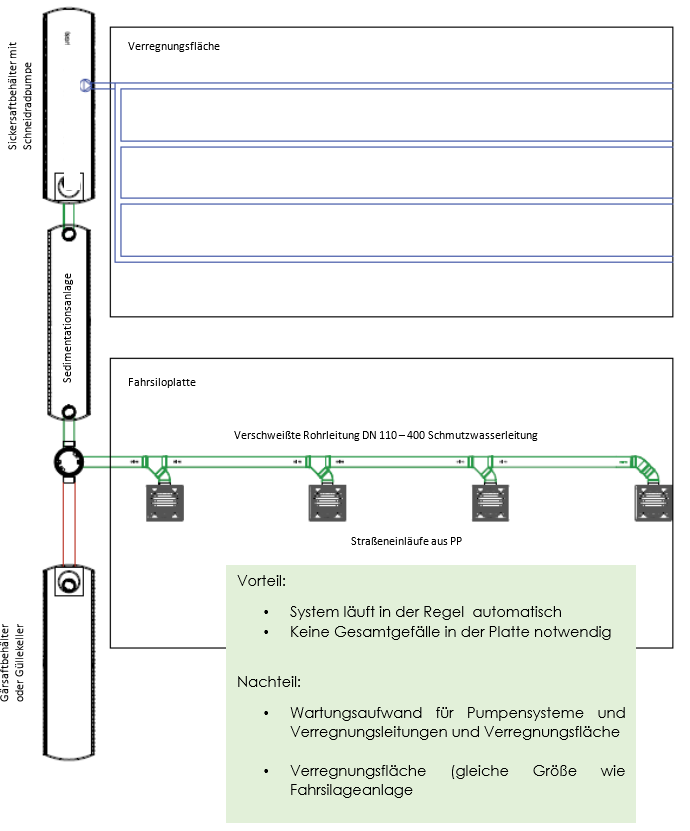

- Driving silo plant with sprinkling of the leachate

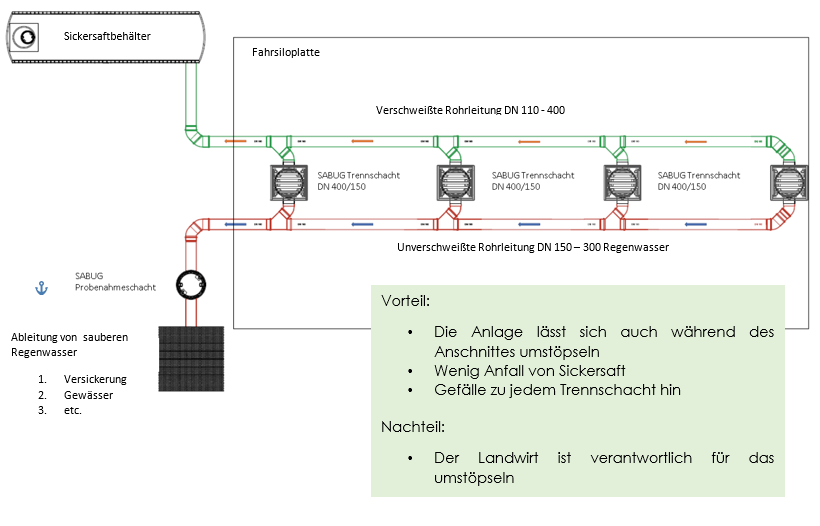

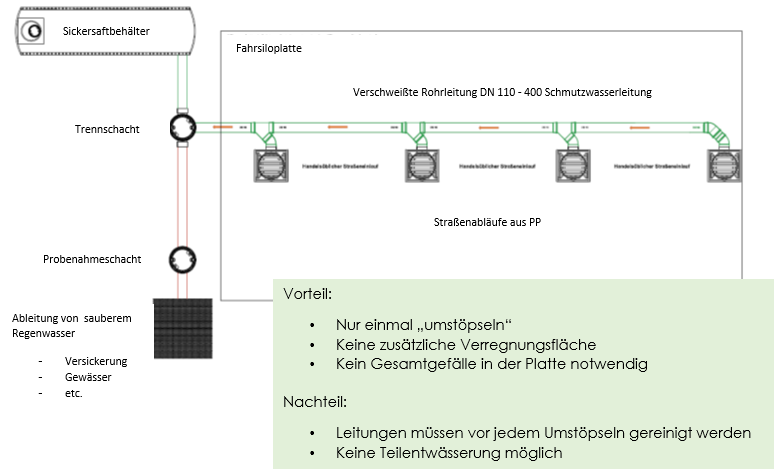

2. driving silo plant with separation shafts

3. driving silo with separating system, outside the silo plate

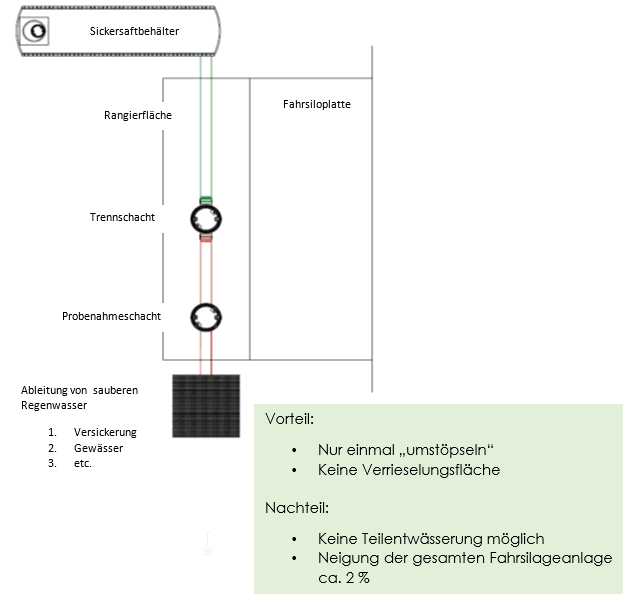

4. driving silo plant with separation shaft, separation on the shunting area

Of course, other designs are also possible. Which version of wastewater drainage or water storage is used is ultimately determined by the operator. But in all cases, the responsible water authorities (lower water authority or the district office) must agree and issue a permit under water law. For this purpose, some documents such as site plans must be submitted. Please also note that not all designs shown here are approved by all lower water authorities and district offices. Please check with your local authority first.

SABUG will be happy to assist you with the design of your drainage system and make suggestions for its execution, which will support the work of the planning offices. The documentation of all Plant parts is of course part of the delivery.

However, the binding planning of the plant can only be carried out by the operator himself or with the help of architects or engineering offices.

… Call us – We are happy to help!

Complete solution for sprinkling or storage tank feeding

For raining or pumping the so-called “polluted rainwater” or seepage, the Sabug offers. a complete system for the tank incl. Settling pit.

The basis of the calculation is the rainfall donation, which must be determined according to DWA 117 in accordance with “KOSTRA” for the construction site of the system. In conjunction with the connected area, this results in a rainfall volume that must be “buffered” by the leachate tank until the pump has gradually pumped the contaminated rainwater onto the rainfall area or into another storage tank. As a rule, the 1-year rainfall event is used as a basis.

Here, the larger the pump, the smaller the reservoir can be designed. However, larger pump have higher power consumption and, of course, are much more expensive. This can have an impact on replacement investments in particular. Because the service life of large and small pumps is the same.

The design of the plant is free of charge and includes cost optimization with regard to tank size and pump capacity. This ensures that the tank is not undersized.

To protect the pump and the sprinkler system itself, we recommend equipping the tanks with a sedimentation unit that separates the coarse material downwards and upwards.