Leak tests according to DIN EN 1610 ff

The tightness of all newly laid sewer pipes must be verified in accordance with the relevant regulations (DIN EN 1610, DWA-A 139). Especially plants for water-polluting wastewater have to prove in detail that all connections are “absolutely” tight, so that no water-polluting substances can get into the soil or even into the groundwater.

As a rule, the systems must be approved by experts and approved for operation. For this purpose, proof of a positive leak test must be provided, among other things.

Today, the leak test is usually carried out by specialized companies that perform the test after the installation is completed. This is associated with not inconsiderable costs and waiting times for the civil engineering company carrying out the work.

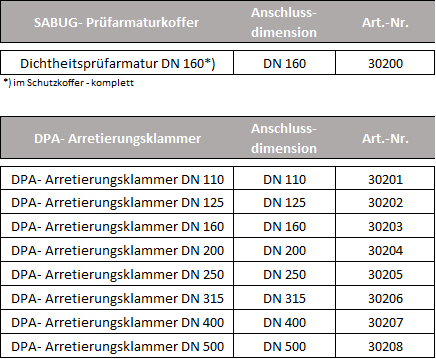

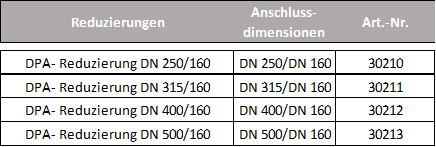

The SABUG leak test system offers the possibility to perform the leak test directly or to prepare the tests for acceptance by the expert. There are no costs for external specialized companies to carry out the leak test, nor waiting times after completion of the pipe construction work. The test fittings are specially designed for leak tests according to DIN EN 1610 or DWA-A 139 for the “L” and “W” methods and for socket constructions corresponding to the pipe dimensions according to DIN EN 14758 and DIN EN 1852 or identical sockets of other pipes. The components are also available for other pipe systems on request.

Advantages :

- Independent performance of the leak test

- Constructive securing of the closing lids against ejection

- Robust and absolutely durable design in stainless steel

- Expansion of the closure lids as needed

- Test armature is equipped with the necessary connections and safety devices

- Significant cost savings compared to conventional shut-off bladders

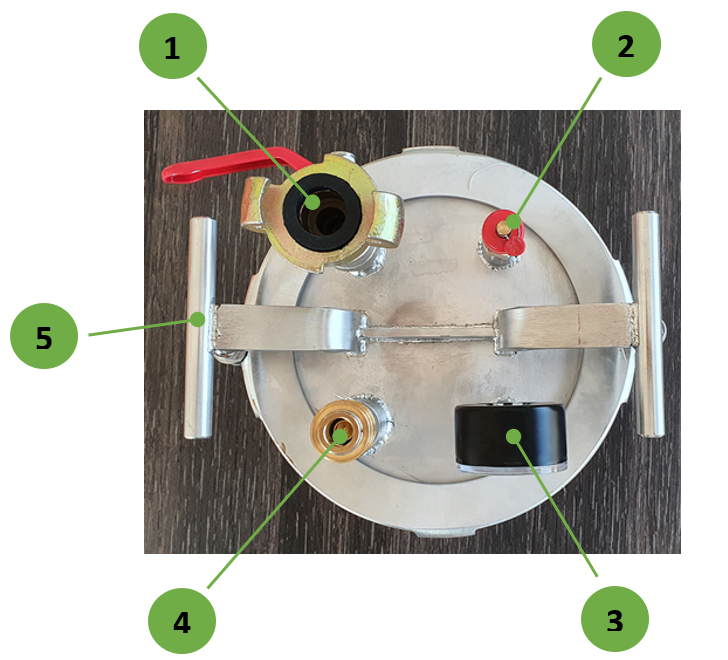

The test fitting and locking clips provide a secure locking system for the pipe sockets. The test fitting is directly equipped with the necessary connections and safety devices:

- Compressed air connection “claw coupling” 1″ for direct connection to a compressor,

- Overpressure valve with 0.5 bar pressure release

- Pressure gauge up to max. 1 bar

- Connection on quick coupling air connection 1/8 ” for the connection of the electronic printer socket

- Handles for easy assembly and disassembly

The locking clamps offer the possibility to secure the pipe sockets closed with commercial socket plugs against being pushed out during leak test.

The clamping force of the locking clamps is greater than the breaking force of the tubes themselves, thus providing a high level of safety against accidents caused by components snapping out. The test armature is supplied incl. the corresponding locking clamp in a protective PP case.

Transition pieces

The test fitting can be inserted in a socket at any point in the wastewater network to be tested. As a rule, most of the pipelines have at min. one point a connection in DN 160. If this is not the case, the SABUG transition pieces, offer a reduction to the necessary dimension.

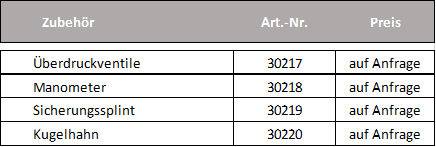

Accessories

All attachment parts of the test fitting are available as spare parts in the accessories.

DPG 1610 leak tester, DIN EN 1610, D WA-A 139

Modern measurement technology for testing the tightness of wastewater pipes and sewers, especially according to DIN 1610 (method W and L) and various other objects. The test device of the company UIT Umwelt – und Ingenieurtechnik from Dresden offers a corresponding test device which can be connected directly to the test fitting. This makes the leak test system from SABUG complete.

Environmental and Engineering Technology GmbH Dresden

Zum Windkanal 21

01109 Dresden

+49 351 88646-00

info@uit-gmbh.de

+49 351 8865774