In principle, all tanks are designed for live loads of up to SLW 60 (10 t wheel load) and groundwater levels up to the top of the tank. The structural analysis is performed as a function of the live loads, groundwater pressure and installation depth.

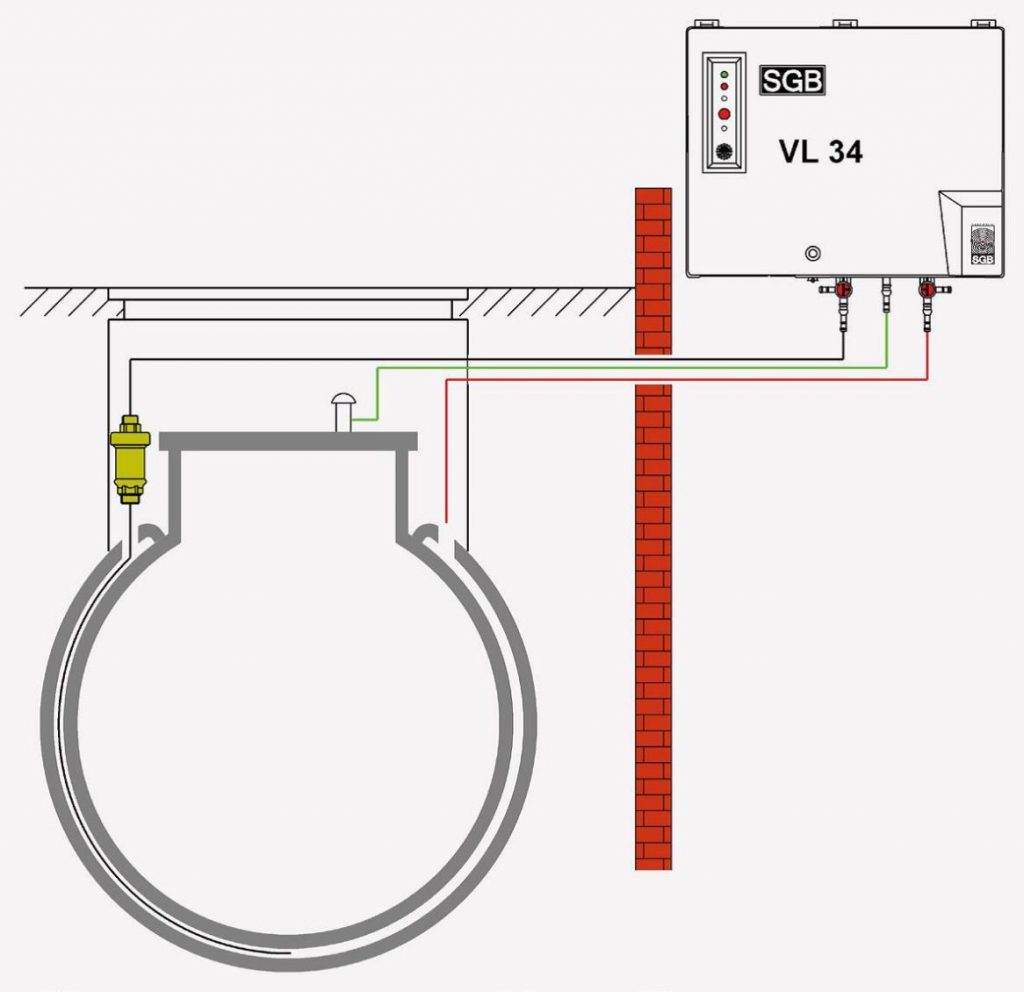

As provided for in the relevant TRwS, all containers are equipped with an electronic leak detector in order to be able to constantly monitor the tightness of the container.

A buoyancy check and a static calculation are supplied on request. If necessary, a sophisticated procedure is used to prevent the tank from being driven up in the event of groundwater being present, with the aid of an appropriately calculated geogrid structure.

The low dead weight (e.g. 50 m³ approx. 4.5 t) enables rapid installation of the prefabricated elements. No truck-mounted crane or other heavy equipment is needed. The SABUG tank system can be used to realize storage systems of various designs from 6 m³ to >1000 m³ storage volume and from 1.00 to 3.00 meters internal diameter. Individual connection options from DN 100 to > DN 600 at the factory.

Up to a storage volume of 100m³, the tanks are delivered to the construction site in a prefabricated component. Larger volumes are welded on site by specially trained SABUG welding teams in a professional and standard-compliant manner.