IP-plus welding system

Tests, approvals, opinions

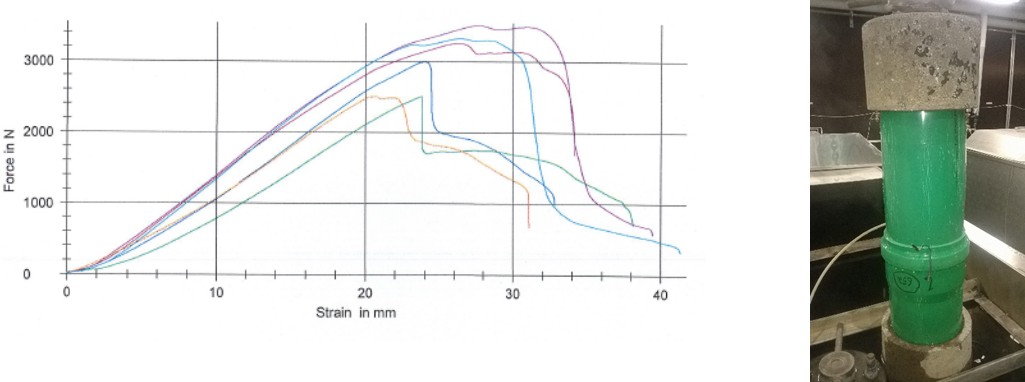

The IP-plus welding system had to prove time and again during the development process and through multiple functional tests that it meets the high requirements. This made it possible to develop an extremely safe and stable welding process.

Of course, the general technical approval of the German Institute for Building Technology has also been granted for this – DIB t (Z-42. 5-553).

We will be pleased to provide you with further evidence from independent test institutes regarding JGS and LAU systems as well as the results of meaningful burst pressure tests > 12 bar) – just ask us!

You can find more documents in the downloads at the bottom of this page.

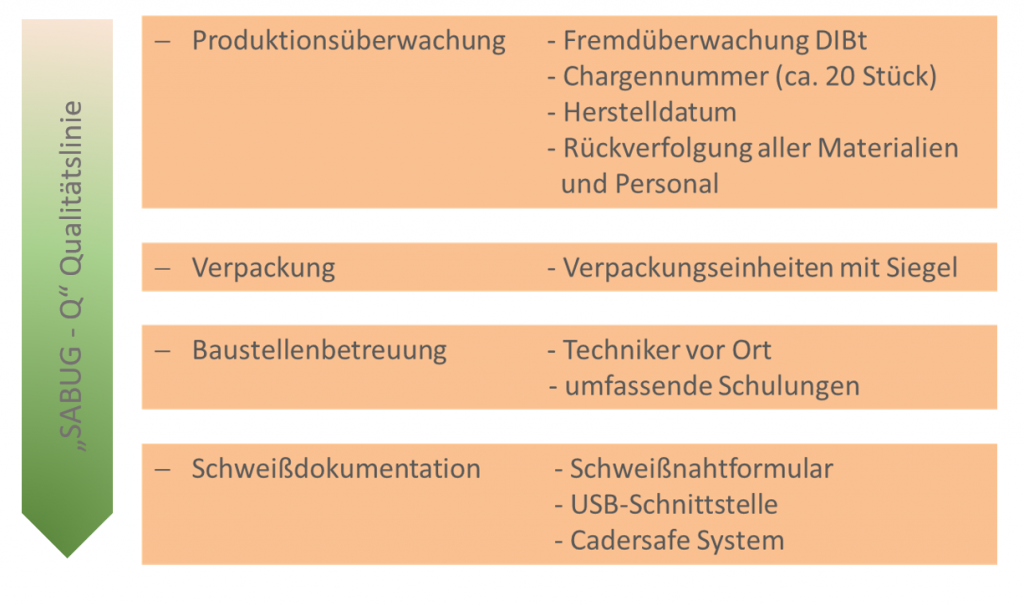

Concept: “SABUG-Q”

Behind the “SABUG-Q” concept is a comprehensive quality assurance program that accompanies the IP-plus welding system in its entirety. From the selection of the basic material and determination of the producer, through the production, to the welding and up to the acceptance on the construction site, the quality of the welding ring is accompanied by us.

Behind the “SABUG-Q” concept is a comprehensive quality assurance program that accompanies the IP-plus welding system in its entirety. From the selection of the basic material and determination of the producer, through the production, to the welding and up to the acceptance on the construction site, the quality of the welding ring is accompanied by us.

All the mechanisms for constantly checking the results eventually lead to the desired outcome:

A tight, long-term stable welded joint that will serve for many years.

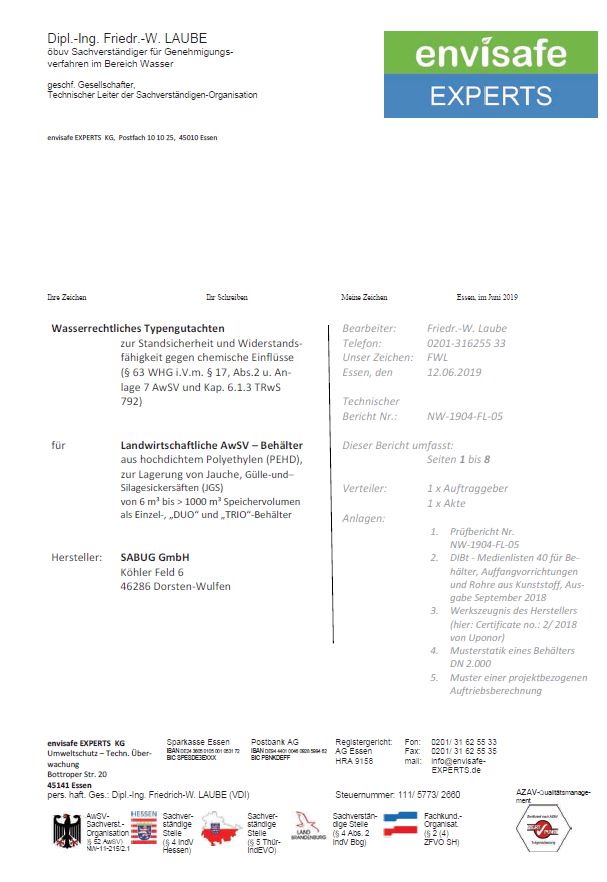

AwSV tank

High-quality professional planning and design is a fundamental condition for a successful project. SABUG GmbH has optimized this approach. Each tank receives detailed documentation with delivery to ensure that the drainage system meets the requirements of the test experts. In addition to the requirements resulting from the water law expertise, this documentation includes a large number of internal tests and inspections to ensure that the product meets all requirements.

AwSV plants:

The high requirements of the AwSV 2018 also demand a high level of quality. A water law type certificate in accordance with § 63 WHG in conjunction with § 17 AwSV confirms the serviceability of the system in accordance with TRWS 792. This means that the tanks can be used in the sensitive AwSV areas.

The documentation of the tanks includes the following information:

- Design elaboration of the tank installation

- Technical data

- Operating instructions

- Declaration of conformity of materials

- Verifiable static calculation

- Leak test according to DIN EN 1610

- Buoyancy check according to DIN 1054 with a safety factor of 1.1 (if groundwater is present)

- Supplementary design according to DIN EN 1295-1 (2002)

- Technical drawing

- Comprehensive installation and assembly instructions

To ensure high quality, every tank and container is put through its paces!

Tests

- MFR values according to EN ISO 1133 (2006)

- Density: [kg/m³] according to EN ISO 1183-1 (2006)

- OIT values according to EN 728 (1999)

Tests on the finished product:

- Ring stiffness according to EN ISO 9969 (2008)

- MFR values according to EN ISO 1133 (2006)

- Tensile strength according to EN 1979 (2002)

- Ring flexibility test according to EN ISO 13968 (2009)

- Leakage tests on fittings and connections according to EN 1277 (2005)

- Water tightness tests according to EN 1053 (1998)

- Seals according to EN 681-1

- Testing of welded joints according to EN 1979 (2002)