Fermentation juice tank – Percolation juice tank

The SABUG tank system made of high-quality, chemically highly resistant polyethylene (PE-HD). The tank or vessel is designed and manufactured according to the customer’s requirements. The system is characterized by high stability and resistance. A comprehensive quality assurance program ensures excellent quality of each tank.

All SABUG JGS tanks have a water law type certificate as proof of suitability for use in accordance with TRwS 792 and in the sense of § 63 WHG in conjunction with § 17 AwSV. The verification is valid for containers from 6 to 1000m³.

In principle, all containers are designed for live loads of up to SLW 60 (10 t wheel load). The structural analysis is performed as a function of the live loads, groundwater pressure and installation depth.

A buoyancy check and a static calculation are supplied on request. If necessary, a sophisticated procedure is used to prevent the tank from being driven up in the event of groundwater being present, with the aid of an appropriately calculated geogrid structure.

The low dead weight (e.g. 50 m³ approx. 4.5 t) enables rapid installation of the prefabricated elements. No truck-mounted crane or other heavy equipment is needed. The SABUG tank system can be used to realize storage systems of various designs from 6 m³ to > 1000 m³ storage volume and from 1.00 to 3.60 meters internal diameter. Individual connection options from DN 100 to > DN 600 at the factory.

Up to a storage volume of 100m³, the tanks are delivered to the construction site in aprefabricated component. Larger volumes are professionally welded on site by specially trained welding teams.

Advantages:

- High static stability – up to traffic loads SLW 60

- High stability against groundwater

- High chemical resistance

- Low weight due to lightweight construction

- Double wall construction

- Flexible adjustment of the required volumes

- Leakage monitorable due to double wall profile

Tank versions:

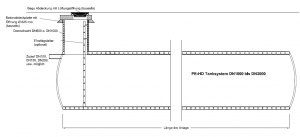

Sabug – JGS – single container

For the storage of polluted rainwater and seepage juices or similar. All tanks are designed with respect to individual requirements. The following data are also processed:

• Rain donation according to KOSTRA

• Surface area size

• Surface conditions

• Pump performance

• Traffic loads

• Groundwater level

• Requirements from authorities

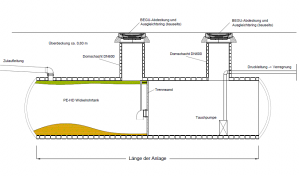

Sabug – JGS – “DUO” container

For the storage of polluted rainwater and seepage juices incl. Sedimentation chamber. The volume of the settling chamber is added to ¾ of the storage volume. This leaves 1/8 of the total volume as storage space for settled substances. If necessary, these can be easily pumped out through the access opening.

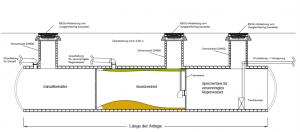

Sabug – JGS – “Trio” tank

For the storage of polluted rainwater and seepage juices incl. Sedimentation chamber. As well as storage of fermentation juices in a separate but directly integrated tank. Here, too, ¾ of the volume of the settling chamber is added to the storage volume. This leaves 1/8 of the total volume as storage space for settled substances. If necessary, these can be easily pumped out through the access opening.

The contents of the digestate tank can also be pumped out and spread on the fields after the blocking period.

Please refer to the assembly instructions (www.sabug.de/download) for the possible designs and installation options.

You can find more information in the following Areas