Quality assurance container

Each tank receives detailed documentation with delivery to ensure that the drainage system meets the requirements of the inspectors.

The documentation of the containers includes the following information:

- Planning elaboration of the tank installation

- European approval with quality control of the pipe systems from ITB (Building Research Institute); No. AT-15-7404/2011

- Welding work is carried out according to DVS 2207

- Structural analysis taking into account the SLW 60 traffic loads and the groundwater in the vicinity.

- Buoyancy check according to DIN 1054 with a safety factor of 1.1

- Supplementary layout according to DIN EN 1295-1 (2002)

- Technical drawing

- Comprehensive installation instructions

To ensure high quality, every tank and container is put through intensive testing.

Tests:

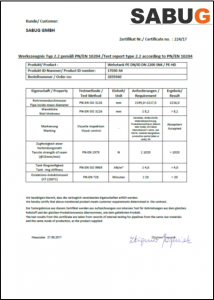

PE raw material -tests:

- MFR values according to EN ISO 1133 (2006)

- Density: [kg/m³] according to EN ISO 1183-1 (2006)

- OIT values according to EN 728 (1999)

Tests on the finished product:

- Ring stiffness according to EN ISO 9969 (2008)

- MFR-Werte nach EN ISO 1133 (2006)

- Tensile strength according to EN 1979 (2002)

- Ring flexibility test according to EN ISO 13968 (2009)

- Leakage tests on fittings and connections according to EN 1277 (2005)

- Water tightness tests according to EN 1053 (1998)

- Seals according to EN 681-1

- Testing of welded joints according to EN 1979 (2002)

Quality Assurance Separation Shafts:

All DN 315 and DN 400 separation shafts are given a serial number during production. This also allows the manufacturing processes to be traced back at a later date.

Furthermore, they are subjected to a leak test according to DIN EN 1610 during production. (0,5 bar, 15 min.) This ensures. That both chambers are tightly welded to each other and to the ground. Each chamber then has a leak test record.